Alpha Glass

$28.00

50ml Bottle Size

- Professional / DIY friendly

- Lasts 2 - 3 years

- Robust waster repellency

- Enhances visibility

- Harsh chemical resistance

- Minimizes fingerprints

- Boosts de-icing

-

Same day shipping before 12:30 PM CST

-

Free shipping on orders over $99

-

Easy 14-day return policy

-

100% satisfaction guaranteed

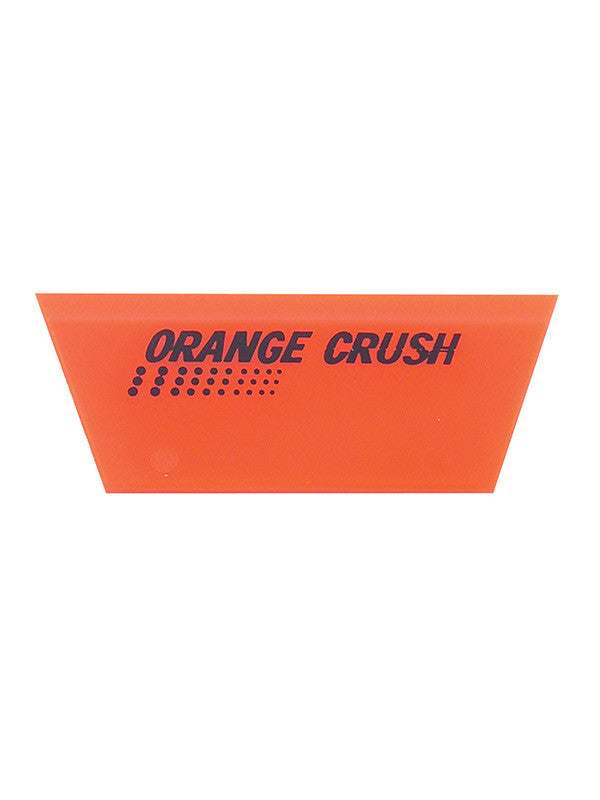

Pairs well with...

- Professional and DIY friendly

- Experience 2 - 3 years of exceptional repellency

- Robust water repellency results in striking runoff for a clear view

- Enhances visibility during challenging weather conditions

- Withstands harsh chemicals and pollutants for long-lasting protection

- Effectively minimizes fingerprints with advanced oil resistance

- Boosts de-icing performance for added functionality

Application Instructions

How do I install Alpha Glass?

SGS Certification

100% CERTIFIED TOUGH

We're beyond excited to unveil the world's strongest ceramic coatings, and we've got the official certification to back it up. Coating Farm USA is one of the select few to have our products certified by the renowned experts at SGS, a global leader in inspection, verification, testing, and certification. And get this – our ceramic coatings scored a 10H+ hardness rating, making our coatings the only ones in the industry with that top-tier hardness rating. So yeah, when we say we're talking about the world's strongest ceramic coatings for your ride, we mean it.

THE SGS

SGS, also known as Société Générale de Surveillance, is like the OG in inspection, verification, testing, and certification. They've been doing their thing since 1878, with offices and labs all over the globe. From making sure products meet industry standards to giving them the thumbs-up through tough testing, SGS has got it covered.

WHY WE TESTED

We were so confident in our products that we sent samples of our ceramic coatings to SGS for testing and certification. Few companies take this step due to its cost and the prevalence of cheaply manufactured ceramic coatings that offer minimal protection. Some claim to have a 10H hardness without any supporting data. Others discredit the 9H or 10H badges because their coatings have failed similar independent tests, undermining the credibility of the certification process. At Coating Farm, we believe in transparency and credibility, which is why we initiated testing and obtained certification.

HOW WE TESTED

So, how did we snag that impressive 10H+ hardness rating from SGS? Let's break it down. You see, there's a whole lot of confusion swirling around about what these ratings actually signify. At the core of it all is the pencil hardness test, which gauges the scratch resistance of a ceramic coating by running pencils of varying hardness levels across a coated surface. Picture this: if a coating earns a 10H pencil equivalent, it means it can withstand the scrape of a 10H pencil without a scratch. These pencils range from super soft lead (2H) to crazy hard (10H).

WHAT MATTERS

Generally speaking, on the same scale, most car paintwork is between 4H to 6H, so the Coating Farm ceramic coating offers more protection. It does not mean that it can’t be scratched at all or that stone chips can’t occur. However it does act as a harder and more scratch resistant surface than your paintwork alone. It acts as a sacrificial layer that if damaged, can be machine polished without harming your paint’s clear lacquer coat and then re-coated.

What is a ceramic coating?

A ceramic coating is a liquid polymer applied to a vehicle's exterior surfaces. Once cured, it chemically bonds with the factory paint, forming a protective layer that shields against environmental contaminants, UV rays, bird droppings, tree sap, and more. This results in a durable, long-lasting finish that enhances the vehicle's appearance and simplifies maintenance. Coating Farm USA's ceramic coatings offer exceptional longevity and strength, providing unparalleled protection for your vehicle.

What are the benefits of a ceramic coating?

At Coating Farm USA, we're proud to bring you the incredible benefits of our ceramic coatings. Here's why investing in our products is a game-changer for your vehicle or other surfaces:

- Armor-Like Protection: Our ceramic coatings create a robust, protective shield that defends against scratches, swirl marks, and environmental contaminants, ensuring your vehicle stays looking pristine.

- Long-Lasting Brilliance: Experience enduring protection with our coatings that outlast traditional waxes and sealants, keeping your surfaces shielded for years with minimal maintenance.

- Defend Against the Elements: Our coatings act as a powerful barrier against damaging UV rays, preventing oxidation and maintaining the vibrant look of your vehicle's paint.

- Say Goodbye to Water Woes: Enjoy the hydrophobic magic of our coatings, making water bead up and roll off effortlessly. This not only looks impressive but also makes cleaning a breeze, reducing the chance of water stains.

- Chemical Warrior: Our coatings resist harsh chemicals, bird droppings, tree sap, and other contaminants, ensuring your vehicle remains untarnished by everyday hazards.

- Effortless Maintenance: With self-cleaning properties and resistance to contaminants, maintaining your surfaces becomes a stress-free task, giving you more time to enjoy your vehicle.

- Showroom-Worthy Shine: Our coatings enhance the depth and gloss of your vehicle's paint, delivering a finish that mirrors the beauty of a showroom.

- Invest Wisely: While the initial application involves an investment, the long-lasting protection and reduced need for frequent detailing make our ceramic coatings a cost-effective choice in the long run.

- Preserving Your Investment: Protecting your vehicle with our coatings not only enhances its appearance but also safeguards its resale value by maintaining its original condition.

- Versatile Solutions: Explore the versatility of our coatings beyond automobiles – they can be applied to various surfaces, ensuring all your cherished possessions receive the same high-level protection.

Choosing Coating Farm USA means choosing unparalleled protection and a commitment to excellence. Invest in our ceramic coatings to elevate the aesthetics, durability, and longevity of your valued possessions.

What does SGS-certified mean?

Established in 1878, SGS is a globally recognized leader in inspection, verification, testing, and certification services, operating across diverse industries to ensure products meet industry standards and regulations through rigorous testing and validation processes. SGS certification serves as a prestigious mark of excellence, symbolizing the rigorous testing and validation of product quality and performance. Specifically for Coating Farm USA's ceramic coatings, our SGS certification confirms the hardness of our products, with ratings of 9H and 10H. These ratings indicate the level of hardness and durability of our coatings, ensuring superior protection for your vehicle's surfaces.

How long do your coatings last?

The durability of the coating hinges on factors like the coating type and the car's operating and storage conditions, with maintenance playing a pivotal role. Consider Alpha Prime Graphene 10H, meticulously crafted with our patented blend of graphene plus carbon nanotubes, showcasing an impressive lifespan of 9+ years when applied to a well-maintained car.

Alpha Prime Graphene 10H exhibits chemical resistance, ensuring its stability against robust car wash shampoos and cleaning agents. However, it's important to note that the product's lifespan can be compromised by aggressive washing techniques, such as brushes or automatic car washes. To optimize longevity, we advocate the use of microfiber cloths for car washing, harnessing the powerful hydrophobic properties of our ceramic coatings that simplify cleanup.

Consistent and proper maintenance is imperative for achieving optimal results and ensuring the lasting effectiveness of any of our products. Additionally, it's essential to be mindful that ceramic coatings can be removed through abrasive means like machine polishing, cutting compounds, or cut and polish procedures. Neglecting regular washing can diminish the performance and durability of the product, underscoring the importance of proactive care to preserve the coating's effectiveness over time.

What are carbon nanotubes and why do they matter?

Carbon nanotubes are cylindrical structures made of carbon atoms, resembling microscopic tubes. What sets our ceramic coatings at Coating Farm USA apart is our patented formula that combines carbon nanotubes with graphene, creating coatings with extraordinary strength and resilience. This innovative blend of advanced materials is pivotal for the following reasons:

- Unprecedented Strength: Our proprietary formula reinforces ceramic coatings to an unparalleled level. The synergy between carbon nanotubes and graphene results in a coating that stands strong against scratches, impacts, and external forces, ensuring robust protection for your surfaces.

- Conductive Excellence: With the incorporation of carbon nanotubes and graphene, our coatings boast excellent conductivity. This feature helps dissipate static electricity efficiently, minimizing the risk of dust and particle attraction – particularly crucial for maintaining a pristine appearance in automotive applications.

- Optimized Thermal Conductivity: The high thermal conductivity of carbon nanotubes and graphene in our formula aids in effective heat distribution and dissipation. This is instrumental in regulating temperatures, guarding against overheating, and preserving the integrity of coated surfaces.

- Superior Adhesion: Our patented blend ensures superior adhesion to the substrate, establishing a resilient and enduring bond between the coating and the surface. This elevated adhesion contributes to the long-lasting protection provided by our ceramic coatings.

- Adaptive Flexibility: The structural flexibility inherent in carbon nanotubes and graphene allows our coatings to adapt seamlessly to the movement and changes in the underlying surface. This flexibility prevents issues like cracking or peeling, ensuring consistent and reliable protection over time.

- Featherweight Composition: Despite their extraordinary strength, carbon nanotubes and graphene are lightweight materials. The resulting composition of our ceramic coatings is not only powerful but also lightweight, making it an ideal choice for applications where minimizing added weight is essential.

In essence, the combination of carbon nanotubes and graphene in our patented formula represents the pinnacle of innovation in ceramic coatings. The result is a coating that goes beyond conventional standards, offering unmatched strength, conductivity, and resilience for the ultimate protection of your valued surfaces.

Can I apply your ceramic coatings myself?

At Coating Farm USA, we understand that many enthusiasts prefer a hands-on approach. We offer a range of ceramic coatings tailored to different needs and skill levels.

For those seeking a professional-grade finish with enhanced features, our products like Alpha Prime Graphene 10H and Aqua Coat Prime 9H are excellent choices. These coatings deliver exceptional durability and hydrophobic properties. However, it's important to note that they may require more meticulous preparation, including potential paint correction and extended buffing times.

If you're looking for a more DIY-friendly application without compromising on protection, our Quartz Pro Graphene and Ceramic King 9H coatings are designed with simplicity in mind. These coatings still provide robust protection but may require less buffing time and preparation compared to our professional-grade options.

Here's a quick breakdown:

Alpha Prime Graphene 10H and Aqua Coat Prime 9H:

- Professional-Grade: Ideal for enthusiasts seeking the pinnacle of performance.

- Enhanced Features: Offers advanced features such as extreme hardness and extended durability.

- Preparation: May require meticulous preparation, including potential paint correction.

- Buffing Time: Requires more buffing time for a flawless finish.

Quartz Pro Graphene and Ceramic King 9H:

- DIY-Friendly: Designed for users who prefer a more straightforward application.

- Robust Protection: Provides excellent protection without compromising on quality.

- Preparation: Generally requires less preparation compared to professional-grade coatings.

- Buffing Time: Offers a more manageable buffing process for DIY enthusiasts.

Whichever option you choose, our comprehensive instructions and guidelines accompany each product, ensuring you have the information needed for a successful application. If you have any questions or need assistance, our customer support team is always ready to help you achieve the best results with our ceramic coatings.

Are your ceramic coatings "set it and forget it" type of application?

We understand the desire for hassle-free protection, and while our ceramic coatings provide long-lasting benefits, it's essential to be informed. Here's what you need to know:

- Durable Shielding: Our ceramic coatings offer a robust and semi-permanent protective layer, significantly reducing the need for frequent reapplication when compared to traditional options like wax.

- Routine Maintenance: While they do minimize maintenance efforts, we recommend regular care to ensure sustained performance. Periodic washing and gentle cleaning are simple steps that go a long way in preserving the coating's effectiveness.

- Environmental Considerations: Factors like climate, driving conditions, and exposure to contaminants can influence the coating's performance. Regular assessments and, if necessary, touch-ups contribute to maintaining the level of protection you expect.

- Professional Inspection: Periodic professional inspections can provide a comprehensive evaluation of the coating's condition. This ensures that it continues to deliver the intended benefits, and any issues are addressed promptly.

- DIY-Friendly Maintenance Products: Explore our range of maintenance products specifically designed to complement our ceramic coatings. These DIY-friendly solutions make it easy to enhance the longevity and performance of your coating with straightforward application.

While ceramic coatings are not entirely hands-off, their extended durability and effectiveness make them a low-maintenance, high-performance choice for protecting your vehicle. By incorporating simple maintenance practices and using our recommended products, you'll enjoy consistent and reliable protection over the long term.

How do I prepare my car for a ceramic coating?

Proper preparation is crucial to ensure the optimal performance and longevity of a ceramic coating on your vehicle. Follow these steps to prepare your vehicle effectively:

- Wash Thoroughly: Begin by washing your vehicle with a high-quality car wash soap to remove dirt, grime, and contaminants. Use a microfiber wash mitt and a two-bucket wash method to minimize the risk of introducing scratches.

- Decontaminate the Surface: Clay bar the entire surface to eliminate embedded contaminants like tar, industrial fallout, or tree sap. This step ensures a clean and smooth surface for the ceramic coating to bond to.

- Correct Paint Imperfections: If your vehicle has scratches, swirl marks, or other paint imperfections, consider correcting them with a paint correction process. This may involve polishing or compounding to restore the paint's clarity.

- Surface Inspection: Inspect the vehicle's paintwork under proper lighting conditions. Ensure there are no remaining imperfections or contaminants that could interfere with the bonding of the ceramic coating.

- Ensure Dryness: Allow the vehicle to dry completely before applying the ceramic coating. Avoid direct sunlight to prevent water spots during the drying process.

- Remove Wax and Sealants: If your vehicle has existing wax or sealant layers, remove them using a dedicated wax remover or an isopropyl alcohol solution. This step ensures proper adhesion of the ceramic coating to the paint surface.

- Adjust Surface Temperature: Ideally, apply the ceramic coating in a shaded area with ambient temperatures between 50°F and 80°F (10°C to 27°C). Avoid applying the coating under direct sunlight or on a hot surface.

- Use a Panel Wipe Solution: Prior to applying the ceramic coating, wipe the surface with a panel wipe solution or isopropyl alcohol. This helps eliminate any remaining residues, ensuring a clean surface for the coating to adhere to.

- Applicator Selection: Choose a high-quality applicator to apply the ceramic coating. Follow the manufacturer's instructions regarding the application method and technique.

- Work in Sections: Apply the ceramic coating in small, manageable sections to ensure thorough and even coverage. Buff each section promptly after application to prevent uneven drying and residue.

By adhering to these preparation steps, you'll create an optimal foundation for the ceramic coating, maximizing its effectiveness and longevity on your vehicle's surfaces. Always refer to the specific guidelines provided by the ceramic coating manufacturer for the best results.

Is there anything I need to avoid now that my car has been coated?

Steer clear of automatic and roller brush car washes and refrain from wiping your vehicle when it's dry.

What is a high spot?

A high spot in a ceramic coating refers to an excess or uneven application of the coating that has not been leveled properly. When applying a ceramic coating, it is essential to ensure an even and uniform layer on the surface. High spots occur when there is an excess of coating material that has not been properly distributed or leveled, leading to visible irregularities.

Here are common causes and ways to identify high spots:

- Uneven Application: Applying too much coating in one area without spreading it evenly across the surface can result in high spots.

- Incomplete Leveling: After applying the coating, it needs to be leveled or evenly spread using an applicator or microfiber cloth. Failure to do this can leave concentrated areas of the coating, leading to high spots.

Identifying high spots:

- Visual Inspection: High spots are often visible upon inspection. They may appear as thick or uneven patches on the coated surface.

- Tactile Examination: Running your fingers gently over the coated surface can help detect any areas that feel thicker or rougher than the rest.

Dealing with high spots:

- Buffing: If high spots are identified during the initial curing phase, they can be buffed out using a clean and soft microfiber cloth. Buff the affected area gently until it is level with the rest of the coating.

- Additional Application (if necessary): In some cases, if high spots persist after buffing, a small amount of additional coating may be applied to even out the surface. Ensure proper leveling to avoid creating new high spots.

It's crucial to address high spots promptly to maintain the aesthetic and protective qualities of the ceramic coating. Always follow the manufacturer's guidelines regarding application and curing times to achieve the best results and minimize the risk of high spots. If you have concerns or encounter difficulties, consult with the coating manufacturer or seek professional assistance for proper correction.

What is paint correction?

Paint correction is a meticulous process of restoring and refining the surface of a vehicle's paint by removing imperfections such as swirl marks, scratches, oxidation, and other defects. This is typically done using abrasive compounds, polishes, and machine buffing techniques to level the paint and restore a smooth, flawless finish.

The necessity for paint correction before applying certain ceramic coatings arises due to several reasons:

- Surface Uniformity: Ceramic coatings create a protective layer that bonds directly to the vehicle's paint. If the paint surface has imperfections, such as swirl marks or scratches, applying a ceramic coating without correction would lock in these defects, diminishing the overall appearance and protection.

- Enhanced Bonding: Paint correction ensures a clean and smooth surface for the ceramic coating to adhere to. This promotes better bonding between the coating and the paint, resulting in a more durable and long-lasting protective layer.

- Optimal Results: The goal of ceramic coatings is to provide a high-gloss, clear finish. Paint correction maximizes the clarity and reflectivity of the paint, allowing the coating to enhance the visual appearance of the vehicle to its fullest potential.

- Longevity of Protection: By addressing imperfections before applying a ceramic coating, you prevent potential weak points in the coating's defense against environmental elements. A properly corrected surface ensures that the ceramic coating can deliver robust protection consistently over time.

Steps involved in paint correction:

- Compounding: Using an abrasive compound to remove deeper scratches and defects.

- Polishing: Smoothing the surface further with a polishing compound to eliminate finer imperfections and enhance gloss.

- Finishing: Applying a fine polish or finishing glaze to refine the surface, achieving the desired level of clarity and reflectivity.

In summary, paint correction is a vital preparatory step to ensure the success and effectiveness of certain ceramic coatings. It establishes an optimal foundation by addressing imperfections, promoting strong adhesion, and enhancing the overall visual appeal of the coated surface. Always follow the recommendations of the ceramic coating manufacturer regarding the need for and extent of paint correction for their specific product.

Does a brand-new car need paint protection?

While brand-new vehicles typically have a fresh coat of paint, the need for paint correction can still exist. Here are some considerations:

- Factory Imperfections: Even in brand-new vehicles, there may be minor imperfections introduced during the manufacturing and transportation processes. These can include swirl marks, light scratches, or other surface defects.

- Dealership Handling: Vehicles may undergo various handling processes at the dealership, such as washing, transportation, and detailing. These procedures can sometimes result in minor scratches or swirls, necessitating correction.

- Optimizing Surface Quality: Paint correction is not solely about fixing defects; it's also about optimizing the overall surface quality. Even a new vehicle can benefit from paint correction to enhance the clarity, gloss, and reflectivity of the paint.

- Preparation for Ceramic Coating: If you plan to apply a ceramic coating to your new vehicle, paint correction becomes particularly important. It ensures that the coating adheres to a pristine surface, maximizing its effectiveness and longevity.

It's essential to note that not every brand-new vehicle requires extensive paint correction. Some may have minimal imperfections that can be addressed with a lighter correction process or even skipped altogether. The decision to perform paint correction on a new vehicle depends on the owner's preferences, the desired level of surface perfection, and whether there are plans for additional protective measures like ceramic coatings.

If you're considering paint correction for your brand-new vehicle, it's advisable to consult with detailing professionals or follow the recommendations provided by the ceramic coating manufacturer if you plan to apply such a coating. They can assess the condition of the paint and provide guidance on the most suitable course of action to achieve the desired results.

Why is a ceramic coating superior to a wax application?

At Coating Farm USA, we prioritize delivering unparalleled protection and performance for your vehicle. Here's why our ceramic coatings outshine traditional wax applications:

- Extended Longevity: Our ceramic coatings provide a long-lasting shield, delivering protection that lasts for years, surpassing the lifespan of traditional wax applications.

- Exceptional Durability: Forming a robust, semi-permanent bond with the surface, our ceramic coatings offer superior resistance against scratches, swirls, and environmental contaminants, ensuring enduring protection.

- UV Shielding: Guarding against harmful UV rays, our ceramic coatings prevent paint oxidation and fading over time, offering more effective UV protection compared to conventional waxes.

- Hydrophobic Brilliance: Enjoy the self-cleaning effect of our ceramic coatings as they create a hydrophobic surface, causing water to bead and roll off effortlessly. This feature reduces water spots and simplifies maintenance, setting it apart from traditional wax applications.

- Chemical Resilience: Our ceramic coatings exhibit advanced chemical resistance, providing heightened protection against harsh chemicals, bird droppings, tree sap, and various contaminants, surpassing the capabilities of wax.

- Enhanced Gloss: Elevate the visual appeal of your vehicle with our ceramic coatings that enhance the depth and gloss of the paint, creating a vibrant and captivating finish that surpasses what traditional waxes can achieve.

- Effortless Maintenance: Benefit from reduced and less intensive maintenance with our ceramic coatings. The self-cleaning properties and durability ensure that your vehicle stays looking pristine with minimal effort on your part.

- Cost-Effective Excellence: While the initial investment in a ceramic coating may be higher, the long-term benefits, decreased maintenance costs, and extended protection make it a cost-effective choice in the grand scheme of vehicle care.

Choosing Coating Farm USA means opting for cutting-edge technology and superior protection for your vehicle. Our ceramic coatings go beyond the capabilities of traditional waxes, providing a solution that not only enhances appearance but also ensures long-lasting and comprehensive safeguarding.

Can I use wax over my ceramic coating?

At Coating Farm USA, we recommend following specific guidelines to optimize the performance of our ceramic coatings. While our coatings are engineered to provide robust and long-lasting protection on their own, here are some considerations regarding the use of wax:

- Enhanced Formulation: Our ceramic coatings are meticulously formulated to offer superior protection and durability. Adding traditional wax may not significantly enhance the benefits and could potentially affect the coating's intended performance.

- Manufacturer's Recommendations: Always refer to our product guidelines and recommendations. We provide detailed instructions on the compatibility of our ceramic coatings with other products, including waxes. Following these guidelines ensures you get the best results and longevity from our coatings.

- Tailored Maintenance Solutions: Explore our range of maintenance products designed to work seamlessly with our ceramic coatings. These specialized products, such as our spray-on coatings or detailer sprays, are formulated to complement and enhance the performance of our coatings.

- Consider Layering: Keep in mind that some ceramic coatings form a molecular bond with the paint surface. Applying wax on top may interfere with this bond. If you choose to use additional products, do so cautiously to avoid compromising the effectiveness of our ceramic coatings.

- Longevity of Protection: Our ceramic coatings are engineered for lasting protection, often surpassing the longevity of traditional waxes. They typically do not require frequent reapplication, providing you with sustained benefits over time.

For the best results and to ensure the continued effectiveness of our ceramic coatings, we encourage you to follow our guidelines and use our recommended maintenance products. If you have specific questions or concerns, our customer support team is here to assist you in maximizing the performance and longevity of our coatings on your vehicle.